Web Site:Home >> Products

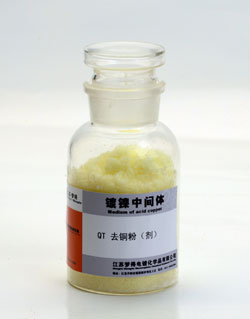

QT

| QT |

|

| Properties |

| Appearance |

White powder |

| Concentration in baths |

0.1-0.2g/L |

| Consumption |

Depend on the amount of copper ions |

| Applications |

| In normal sulphate nickel plating bath, >20mg/L copper impurity can deteriorate the nickel deposit and cause blackening in LCD areas. Compared with low current electrolyzing or raising pH to subside, QT saves a lot of time and nickel. If adding QT 0.2-0.4g/L into bath once a month or ahead of treating nickel-plating bath, the problem of darkening or blackening caused by excessive copper impurity can be resolved. It's a stable, reliable, fast and effective way to maintain the stability of nickel-plating bath. |

| Package and Storage |

| Package |

1000g plastic sealing bag |

| Storage |

Non-dangerous articles, be stored at cool and dry place | |